Kegu Motor Shen Zhen Ke Gu Technology Co.,ltd is an experienced company that designs, develops and manufactures precision transmission systems, High precision brushless motors (EC motors), coreless motors, encoders,,coreless gear motor, and complete miniature and micro drive systems.Kegu Motor is an outstanding manufacturer in the area of micro coreless motor, DC motors, linear motor, coreless gear motor, planetary gear drive system.

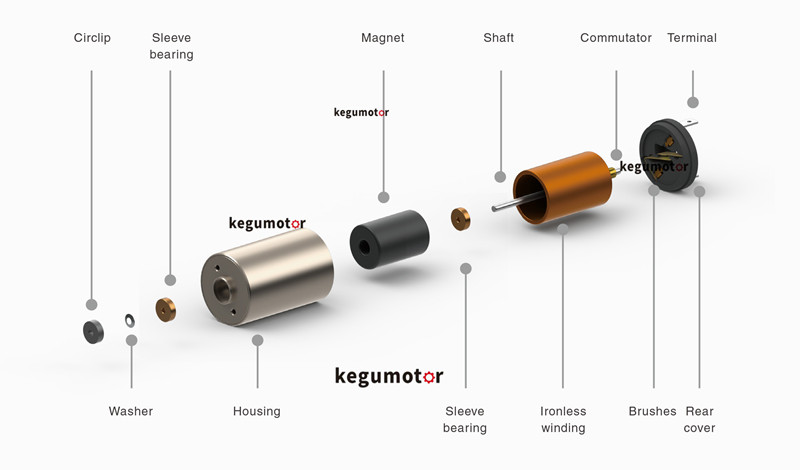

Coreless DC gear motor is made up two parts, precision gearboxs and a coreless dc motor.

Coreless DC gear motor is a type of coreless motor that does not have a winding around a central core. The stator of a coreless DC motor typically consists of two permanent magnets that are mounted on opposite sides of the motor. The rotor of a coreless DC gear motor typically consists of a permanent magnet that is mounted on a shaft.

What are advantages of coreless gear motors: Coreless DC motor doesn’t have a winding around a central core, which means that it can be more efficient than a traditional DC motor. Brush motors also tend to be smaller and lighter than traditional DC motors.

High Performance Low Consumption Coreless Gear Motors,DC Gearmotor Supplier

Coreless DC gear motor is made up two parts, precision gearboxs and a coreless dc motor.

High Performance Low Consumption Coreless Gear Motors,DC Gearmotor Supplier

Coreless DC gear motor is made up two parts, precision gearboxs and a coreless dc motor.

Combination: Precision Gearboxes,Drive Electronics and Encoders

Kegumotor is committed to working with you to design and manufacture a coreless brush motor solution specific to your application needs.

Brush Type: Carbon / Precious Metal / Other

Commutator Material: Precious Metal / Graphite

Nominal Voltage

Output load speed

Power Rating

No-Load and Maximum Current

Load Torque

Rotor Inertia

Ambient Temperature Range

Motor Shaft Material & Size

Motor Shaft Configuration: Offset / Concentric / D Cut / Round / Splined / Other

Overall motor size, Diameter (L, W, H)

Encoder Type: Optical / Hall Effect

Additional Assembly Requirements (lead wires, connectors, pulley, gear, etc.)

Ask 12V Coreless DC Gear Motor Datasheet & Price Now! Fast Reply Within Few Hours! Longer Working Time! Lower Current. New Design Support. Find Best 12V DC Gear Motor Seller From China. Premium Quality & Coreless DC Gear Motor Exporter.

20mm Coreless DC Gear Motor, Model 2016R series

Motor type: PMDC coreless gearmotor

Motor housing (D*F* L): Φ20*16mm

Housing material: SECD-O

Shaft (diameter): 1mm SUS304 steel (nickel coating)

Way of commutation: Precious metal-brush

Structure: 2-pole stator and hollow cup type

Magnet type: Nd-Fe-B

Rotation: CW/CCW and reversible

Motor Name | KG-20P2016R |

Typical Application | Medical equipment、 Home appliance、 Industrial automation |

Nominal voltage | 12V |

No load current | 55mA |

Stall torque | 6.6 kg.cm |

Efficiency | 63% |

Induction of the High Torque 20mm Series Micro Coreless DC Gear Motor 2016R

Specification of the High Torque 20mm Series Micro Coreless DC Gear Motor 2016R

No. |

Motor Model | Operating Voltage | Rated Voltage | No Load Speed | No Load Current | Stall Torque | Stall Current |

V | V | r/min | mA | Nm | A | ||

1 | KG-20P2016R-V1 | 6-12 | 12 | 124 | 55 | 0.66 | 1.1 |

2 | KG-20P2016R-V2 | 6-12 | 12 | 145 | 77 | 0.77 | 1.5 |

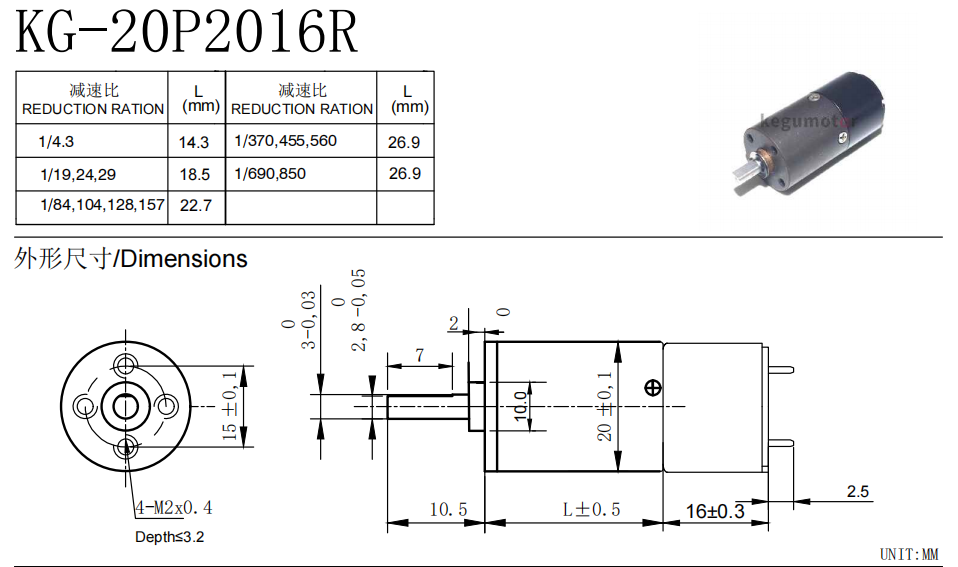

KG-20P2016R 20mm Series Coreless Gear Motor Dimensions 2016R

Keywords:

coreless gear motor, coreless dc gear motor, 6V gear motor,12V gear motor, 20mm motor

This 20MM Series 2016R coreless gear motor is small ,light, precision, reliable control and delicately operate, which can offer high torque and speed for tattoo equipment and medical equipment.

Small vibration offering the best tattoo experience for customer.

Reliable and stable with long lifetime.

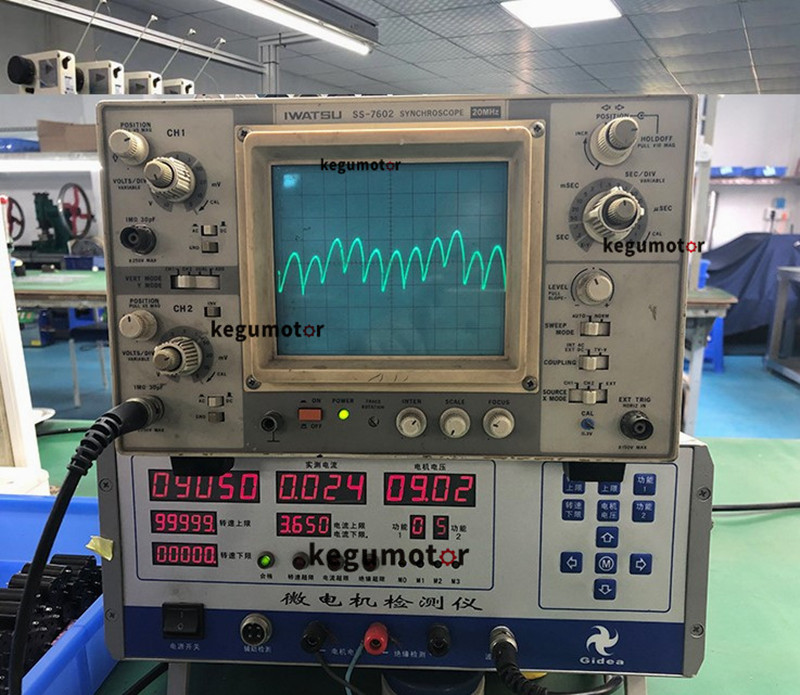

100% complete inspection of the materials after we get from our suppliers and products before ex-factory to ensure the quality for our customer.

The perfect substitute for European motors which can save lots of time and cost for our customer.

80% of coreless motors are customized. At present, the core key materials and components are still imported. KEGU MOTOR provide domestic customers to use international brand quality coreless motors with a higher performance, and continue to improve their product series . Prepare inventory according to plan, independently produce and process customized parts, so that the quality standards and process technology are consistent with the Swiss Maxon.

Custom specification is also available for us.

20mm Coreless Gear Motor, 20mm Hollow Cup Motor, 20mm Slotless Gear Motor,20mm slotless brushless gear motor for Tattoo Machine,Hollow Cup Motor for Tattoo Machine,Tatto Machine Motor, Tatto Machine Coreless Motor, Tatto Machine Hollow Cup Motor,Coreless Gear Motor Manufacturer, Coreless Gear Motor Factory,Coreless Motor China Shenzhen Manufacturer Factory,Customized Motor,Custom Coreless Gearmotor

Coreless brushed motors function similarly to traditional or cored brushed motors. With a coreless design, magnetic fields are induced by applying current and voltage to the rotor windings, which react with the permanent magnet on the stator to convert electrical energy into mechanical energy. A coreless dc motor is typically constructed with rare earth magnets to maximize performance and mechanical strength from such a small form factor. An electric micro motor like this needs the best materials in order to have a high starting torque and rapid mechanical time constant.

The removal of the iron core, within the housing cylinder, leads to other advantages as well. Armature Windings dissipate heat more efficiently without an iron core holding onto the heat in the middle of the motor. This improved thermal performance allows a coreless dc motor to to radiate its heat through the casing, removing the need for air holes of active cooling. In turn the sealed casings help to reduce both audible noise as well as electrical noise or EMI, making coreless motor well suited for applications sensitive to electromagnetic interference.

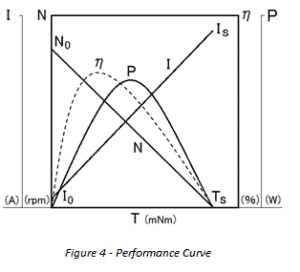

A coreless motor's performance and gearbox performance are combined into one graph by displaying three specific parameters. These three parameters are speed, torque and efficiency. These performance curves are essential when selecting a motor for your application.

Speed/Revolutions (N) – (unit: rpm) indicated as a straight line that shows the relationship between the motor’s torque and speed. It should be used near its peak efficiency to maximize the motor’s potential.

Efficiency (η) – (unit: %) is calculated by the input and output values, represented by the dashed line. To maximize the motor’s potential it should be used near its peak efficiency.

Torque (T) – (unit: gf-cm) this is the load borne by the motor shaft, represented on the X-axis.

Current (I) – (unit: A) indicated by a straight line, from no load to full motor lock. This shows the relationship between amperage and torque.

Output (P) – (unit: W) is the amount of mechanical energy the motor puts out.

Micro DC Coreless Gear Motor Structure

12V coreless motor is a high-speed, high-torque motor that is perfect for a wide range of applications. It features a high power density and low inertia, making it ideal for use in applications where space is limited. Additionally, the coreless design of this motor eliminates cogging and provides for smoother operation.

PREVIOUS:KG-16P1827R 18mm Diameter 27mm Length 12V Coreless Gear Motor

NEXT:KG-22P2232R 22mm Diameter 32mm Length 12V Coreless Gear Motor

PREVIOUS:KG-16P1827R 18mm Diameter 27mm Length 12V Coreless Gear Motor

NEXT:KG-22P2232R 22mm Diameter 32mm Length 12V Coreless Gear Motor

Contact: Mr Liu

Phone: 86-755-27801762

E-mail: sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen